EVA Foam: Properties, Benefits, and Common Applications

EVA foam, short for Ethylene Vinyl Acetate foam, is a versatile and durable material widely used across various industries. Known for its excellent shock absorption, flexibility, and resistance to water and chemicals, EVA foam has become a popular choice for a wide range of applications.

In this blog, we will delve into what EVA foam is, exploring its unique properties and the benefits it offers. Additionally, we will highlight some of the most common uses of EVA foam, showcasing its versatility and essential role in products ranging from sports equipment and footwear to packaging and automotive components.

What is EVA Foam?

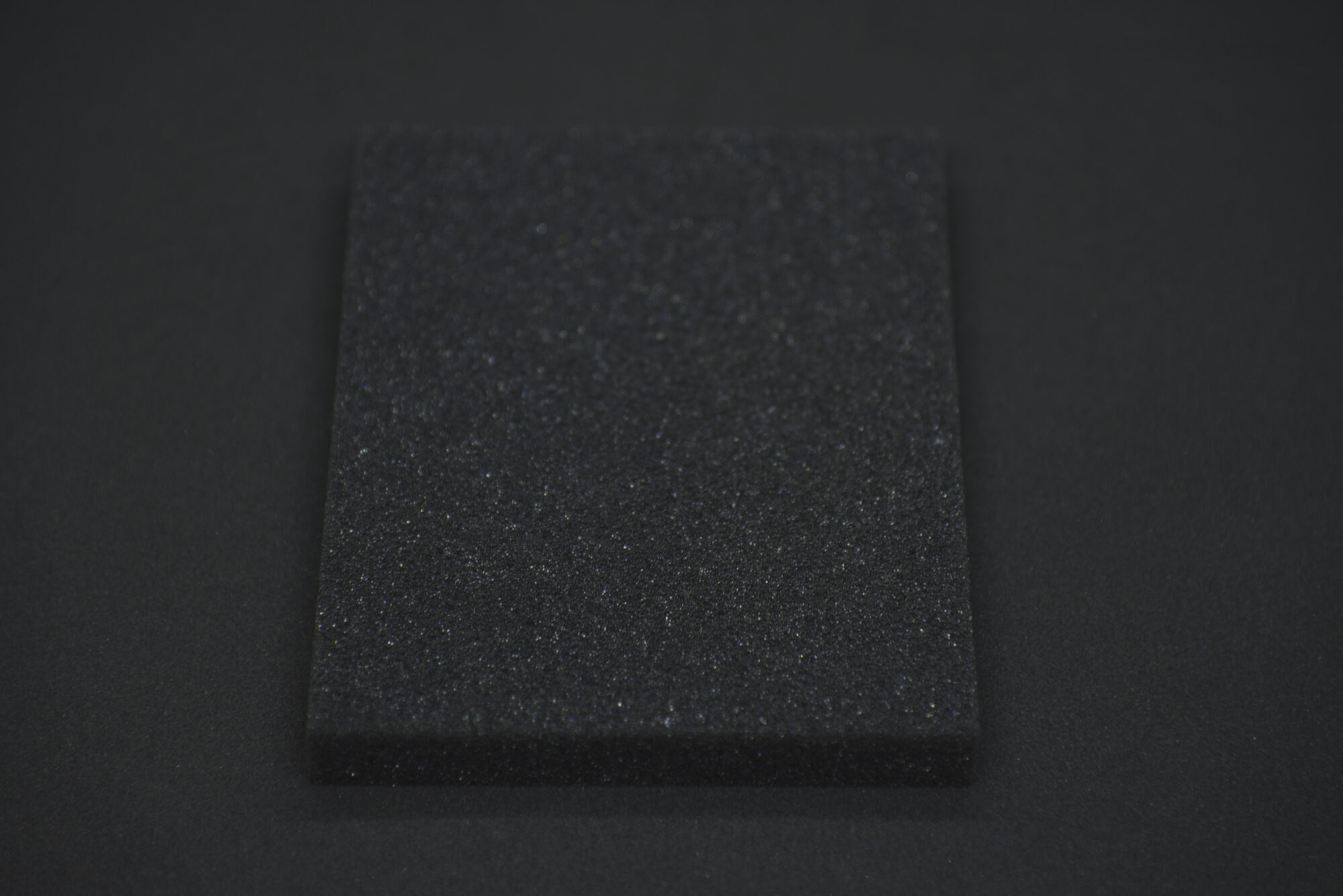

EVA foam, short for Ethylene Vinyl Acetate foam, is a closed-cell copolymer foam that serves as an effective substitute for a variety of traditional materials. Known for its versatility and durability, EVA foam is used across numerous industries due to its unique properties and benefits.

Properties of EVA Foam

EVA foam, or Ethylene Vinyl Acetate foam, is known for its unique combination of properties that make it a versatile material for various applications. Here are the technical properties that make EVA foam so effective:

- Closed-Cell Structure

EVA foam has a fine, uniform closed-cell structure, which means that its cells are not interconnected. This structure provides excellent buoyancy and low water absorption, making it suitable for marine and water-related applications.

- Density

The density of EVA foam can vary, typically ranging from 20 to 150 kg/m³. This range allows EVA foam to be customized for different levels of firmness and flexibility, depending on the specific application requirements.

- Thermal Conductivity

EVA foam has a low thermal conductivity, typically around 0.033 W/m·K. This property makes it an effective thermal insulator, useful in applications where temperature control is important.

- Compression Set

EVA foam exhibits a low compression set, meaning it can quickly recover its original shape after being compressed. This resilience makes it ideal for cushioning and impact absorption applications.

- Tensile Strength

EVA foam has good tensile strength, typically ranging from 0.3 to 0.5 MPa. This strength contributes to its durability and ability to withstand mechanical stresses.

- Elongation at Break

EVA foam can elongate significantly before breaking, with typical values around 200-600%. This high elongation provides flexibility and resistance to tearing under stress.

- Shore Hardness

The Shore hardness of EVA foam can be adjusted during production, typically ranging from 25 to 60 Shore A. This allows for customization of the foam’s firmness for different applications.

- UV Resistance

EVA foam has good resistance to ultraviolet (UV) radiation, which helps prevent degradation when exposed to sunlight. This property extends the material’s lifespan in outdoor applications.

- Chemical Resistance

EVA foam is resistant to many chemicals, including oils, fuels, and solvents. This resistance makes it suitable for use in harsh chemical environments.

Industries Using EVA Foam

EVA foam’s unique combination of flexibility, durability, and resistance to environmental factors makes it an indispensable material across a wide range of industries. Its ability to be customized and molded into different shapes and sizes further enhances its utility in various applications.

- Automotive: EVA foam is used in automotive applications for padding, seals, and insulation. Its impact absorption and thermal insulation properties make it ideal for these uses.

- Building and Construction: In the construction industry, EVA foam is utilized for thermal insulation, soundproofing, and as cushioning material in various building components.

- Sports and Recreation: EVA foam is widely used in sports equipment such as padding for helmets, gloves, ski boots, and bicycle saddles. Its shock absorption and lightweight properties enhance performance and safety in sports gear.

- Footwear: EVA foam is a popular material in the footwear industry, particularly in sports shoes, slippers, and sandals. It provides excellent cushioning, forms to fit the foot, and is lightweight, making it comfortable and durable.

- Healthcare: EVA foam is used in biomedical applications, such as drug delivery systems, mouth guards, and orthopedic products. Its biocompatibility and inert nature make it suitable for medical uses.

- Packaging: EVA foam is employed in packaging for its cushioning and protective properties. It helps protect delicate items during shipping and handling.

- Marine: Due to its buoyancy and low water absorption, EVA foam is used in fishing gear, water sports equipment, and floating eyewear.

- Consumer Products: EVA foam is also found in a variety of consumer products, including foam stickers for crafts, hot glue sticks, and even floating keychains.

- Electronics: EVA foam is used in electronic applications to provide insulation and cushioning for sensitive components.

Benefits and Common Uses of EVA Foam

EVA foam offers numerous benefits that make it a preferred material in a variety of applications across multiple industries. Here are some of the key benefits and common uses of EVA foam:

Impact and Vibration Absorption

EVA foam is known for its excellent impact and vibration absorption properties. This makes it ideal for cushioning and protective applications, ensuring that delicate items and sensitive components are safeguarded against shocks and vibrations.

Example: Used in sports equipment padding such as helmets, gloves, and ski boots.

Durability and Flexibility

EVA foam retains its flexibility and resilience, even under compression and at low temperatures. Its ability to quickly recover from impacts and its resistance to wear and tear make it a durable material for long-term use.

Example: Employed in automotive padding and seals for enhanced comfort and safety.

Environmental Resistance

EVA foam offers good resistance to UV radiation, stress-cracking, and a wide range of chemicals, oils, and fuels. Its waterproof properties further enhance its suitability for outdoor and harsh environment applications.

Example: Utilized in marine gear and fishing equipment due to its buoyancy and water resistance.

Thermal and Acoustic Insulation

EVA foam provides effective thermal insulation and soundproofing, making it useful in applications that require temperature control and noise reduction.

Example: Used in building and construction for thermal insulation and soundproofing.

Buoyancy

EVA foam is buoyant and absorbs minimal water, which makes it an excellent material for marine and water-related applications.

Example: Applied in floating eyewear and fishing rod handles.

Aesthetic Versatility

EVA foam can be easily colored and molded into various shapes and sizes, offering aesthetic versatility for product design. It maintains good gloss and clarity, enhancing the appearance of finished products.

Example: Used in footwear, particularly in sports shoes and sandals for its cushioning and custom fit.

For more information on related packaging solutions, explore our pages on POF shrink film, flexible packaging, and BOPP film.

Discover the Versatility of EVA Foam with Flexipack

Ready to enhance your products with the superior properties of EVA foam? Flexipack offers high-quality EVA foam solutions tailored to meet the specific needs of various industries, from automotive and construction to sports and healthcare.

Contact our packaging experts now to arrange your free consultation and learn how Flexipack’s EVA foam can benefit your business. Our team is dedicated to providing customized solutions that ensure the durability, flexibility, and performance of your products.

Get in touch with us today and explore the endless possibilities of EVA foam with Flexipack.